- Amada Ap100 Software Tutorial Pdf

- Akai Professional Download Drivers Free

- Amada Ap100 software, free download

- Amada Ap100 Software Manual

Quickly turning 3D-CAD designs into the fully formed component is easily possible using the BendCAM CAM solution. The software creates the bending sequence in manual of semi-automatic mode, giving the user the ability to determine the tools and machine configuration.

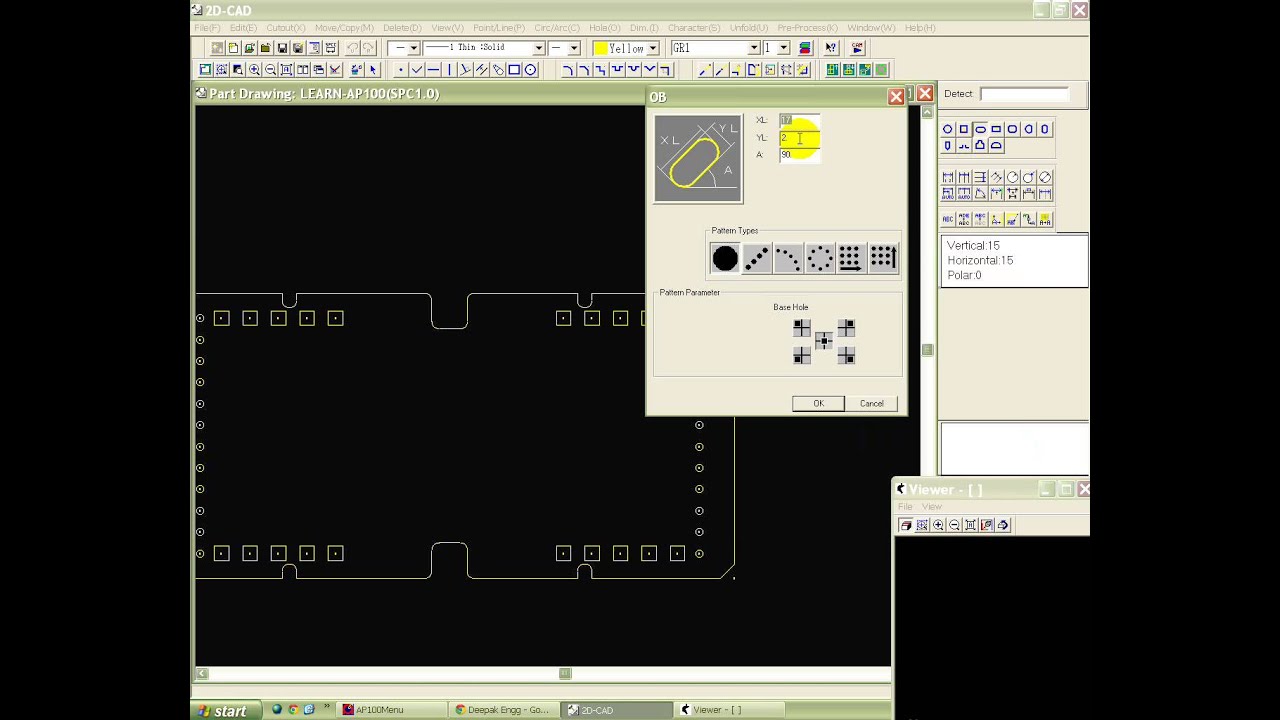

Selection criteria are used to automatically select tools. The software relies on standard and special tools from the central tool library on the AP100 SDD server.

BendCAM reduces the time required to prepare programs and simplifies the machine setup process, therefore reducing machine downtime. The software automatically calculates the best possible bending sequences, then immediately performs a collision check, and also automatically programs the required back gauges.

The user can make manual corrections during the 3D simulation of the current bending sequence. The software then generates the corresponding NC program for the press brake. AstroCAM stores all production relevant data in the central AP100 SDD database. Programs are manually read from the database into the machine control, or alternatively by means of barcode scanner.

BendCAM can be used to externally program AMADA press brakes with AMNC control.

BendCAM reads unfold drawings with bending attributes and automatically creates

Amada Ap100 Software Tutorial Pdf

BENDING Solution Pack: software solution for bending machines The pack comprises the following applications: AP100 EU PRODUCTION DESIGNER VPSS 3i BEND. The prototyping flow initially involves assigning sheet metal attributes to 2D and 3D drawings and saving them in a database using AP100 EU and PRODUCTION DESIGNER. AMADA software solutions are developed with the objective of increasing customer productivity. AMADA provides complete blanking, bending, tube, robot and welding software packs solutions.

Akai Professional Download Drivers Free

Amada Ap100 software, free download

- Bending data

- Bending sequence

- Die selection

- Die layout

- Process simulation

- NC data

- Form output

Amada Ap100 Software Manual

Features

- Time savings by calculating the optimum bending sequence

- Material savings by simulating instead of performing test runs

- Collision checks increase margin of error

- Automated programming of back gauges

- Fast production startup without test phase

- Increased machine utilization by limiting shop floor programming time